When I first looked into custom premium plastic water bottles, I faced confusion over minimum orders, hidden fees, and unclear timelines. This uncertainty created stress and slowed down my projects.

Ordering custom premium plastic water bottles requires understanding minimum order quantities1, design options, lead times, additional costs2, and the availability of design proofs3. Clear knowledge of these details helps avoid unexpected surprises.

Over the years, I've learned to simplify the ordering process. I'll share everything clearly, step by step, based on my own experiences.

What are the minimum order quantities for custom premium plastic water bottles?

When I started, understanding minimum order quantities (MOQ) was tricky. I didn't want to order too much but needed enough bottles to meet demands.

Typical MOQs for custom premium plastic bottles range from 500 to 1,000 units for standard customizations like logos or colors. For completely new designs or shapes, MOQs usually rise to around 5,000 units or more.

Understanding MOQs Clearly

| Customization Type | Typical MOQ |

|---|---|

| Logo printing only | 500–1,000 units |

| Custom colors | 1,000–2,000 units |

| Completely new shape | 5,000+ units |

My MOQ Advice

If your order quantities fluctuate, negotiate clearly with suppliers. I've often secured lower MOQs by discussing long-term cooperation upfront.

Can I see examples of custom designs available for premium plastic water bottles?

I once placed a custom order without seeing enough examples. The results disappointed me, and I learned to always check existing designs first.

Reliable suppliers openly share design examples, showcasing options like logo placement, printing styles, color variations, and unique shapes. Always request clear photos or physical samples.

Examples of Common Custom Designs

| Custom Option | Description |

|---|---|

| Logo Printing | Silk-screen, UV printing, heat-transfer |

| Gradient Colors | Two-tone and gradient color effects |

| Special Lids | Flip-top, sports lid, straw lid |

| Unique Shapes | Curved or ergonomic shapes |

How Examples Improved My Experience

By reviewing physical samples and clear photographs beforehand, I gained confidence and avoided costly disappointments in production.

How long does it take to receive custom premium plastic water bottles after ordering?

Lead times initially caused me headaches. Misjudging timelines meant missing events or promotional opportunities.

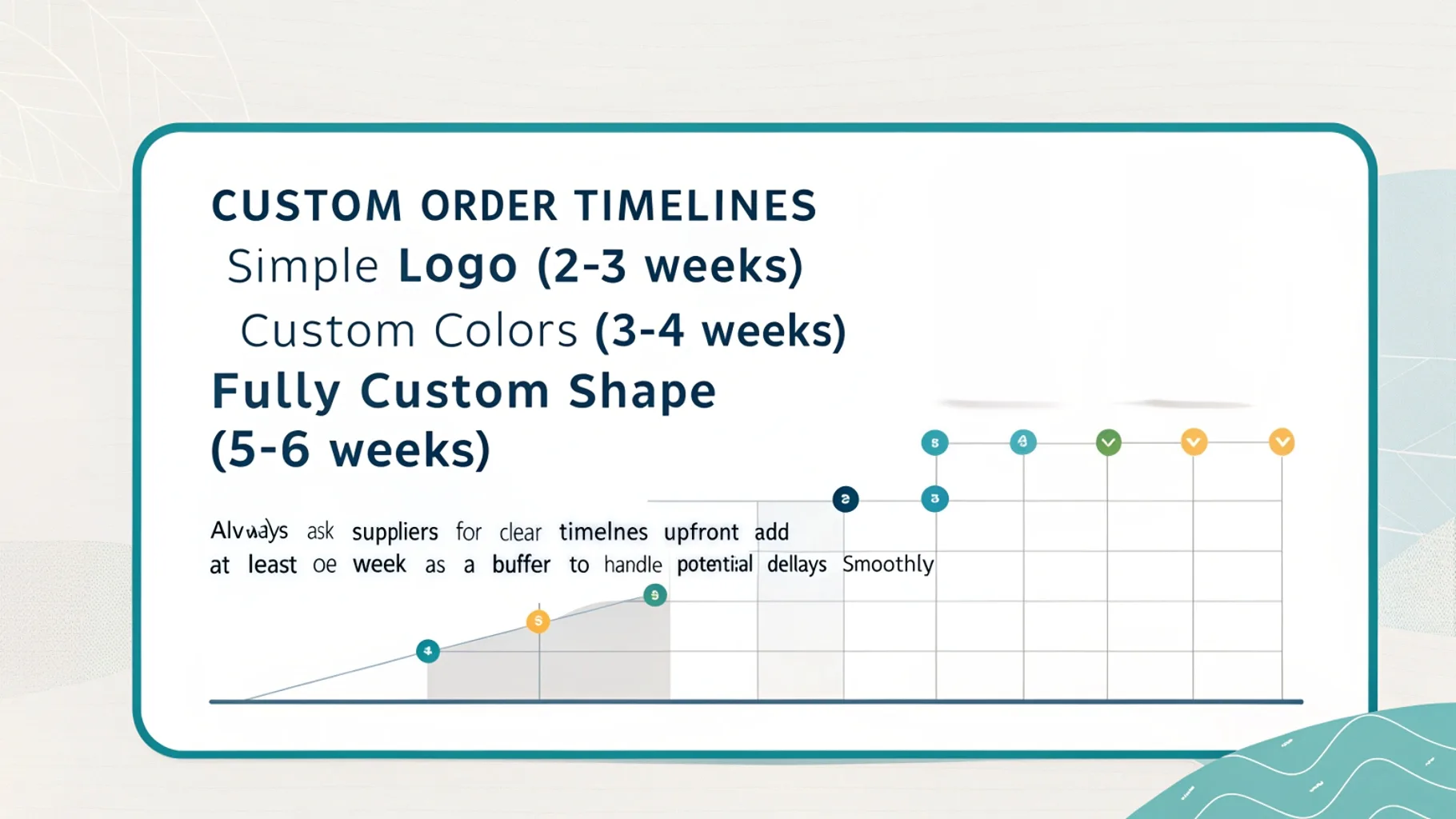

Typical production lead times for custom plastic water bottles range from 3 to 5 weeks, depending on complexity. Simple logo prints take around 2–3 weeks, while fully custom shapes might require 5–6 weeks or more.

Custom Order Timelines Clearly Explained

| Customization Level | Lead Time |

|---|---|

| Simple Logo | 2–3 weeks |

| Custom Colors | 3–4 weeks |

| Fully Custom Shape | 5–6 weeks or longer |

My Lead Time Tips

Always ask suppliers for clear timelines upfront. Add at least one week as a buffer to handle potential delays smoothly.

Are there any additional costs for custom designs on premium plastic water bottles?

Hidden fees frustrated me early in my career. Clearly understanding all costs became critical for budgeting effectively.

Custom designs usually have extra fees for mold creation, complex logo prints, special packaging, or Pantone-matched colors. Transparent suppliers clearly outline these extra costs upfront.

Common Extra Costs for Custom Bottles

| Additional Cost | When It Applies | Typical Fee |

|---|---|---|

| Mold Creation | Unique shapes | $1,500–$5,000 |

| Complex Logos | Multiple colors | $0.20–$0.50 per unit |

| Pantone Matching | Custom colors | $100–$300 per color |

| Special Packaging | Custom branding | Varies widely |

My Advice on Avoiding Hidden Fees

Always request an itemized quotation. I learned transparency is critical; clear communication prevents unpleasant surprises.

Do any suppliers offer a design proof before producing custom premium plastic water bottles?

Design proofs once seemed unnecessary to me—until I faced production errors that proofs could have prevented. Now, I always request them.

Reliable suppliers provide digital proofs or physical samples before full production begins. Proofs let you verify the design carefully and avoid costly mistakes or misprints.

Benefits of Design Proofs

| Proof Type | Advantages | Typical Timeline |

|---|---|---|

| Digital Proof | Quick verification, low cost | 1–2 days |

| Physical Sample | Accurate representation | 5–7 days |

My Proof Experience

I always request a digital proof first. For large orders or unique designs, I ask for a physical sample. These proofs have consistently protected me from expensive errors.

Conclusion

Ordering custom premium plastic water bottles doesn't need to be complicated. Clear communication about minimum order quantities, custom options, timelines, additional costs, and design proofs ensures smooth production, satisfied clients, and successful projects. These simple strategies transformed my ordering process and improved my business significantly.

-

Understanding minimum order quantities is crucial for effective budgeting and planning. Explore this link to gain insights into MOQs and avoid costly mistakes. ↩

-

Hidden fees can derail your budget. Learn about common additional costs to ensure transparency and avoid unexpected expenses in your orders. ↩

-

Design proofs can prevent costly production errors. Discover why they are essential in the custom ordering process and how they can save you money. ↩