Premium Stainless Steel Water Bottles – Built for Your Business

Partner with CupCraft Supply for durable, customizable, and eco-friendly drinkware that reflects your brand’s values. Quality-first solutions, delivered on time—every time.

Partner with CupCraft Supply for durable, customizable, and eco-friendly drinkware that reflects your brand’s values. Quality-first solutions, delivered on time—every time.

Premium stainless steel water bottles are crafted from food-grade 18/8 stainless steel, ensuring durability, rust resistance, and a sleek, modern look. With double-wall insulation and leak-proof design, they’re perfect for sports, office use, or upscale branding. CupCraft Supply offers wholesale solutions for businesses seeking eco-friendly, high-performance drinkware that elevates their image.

Pair your custom colors with add-ons that amplify your brand.

At CupCraft Supply, we get it—your business needs reliable, high-quality drinkware that fits your budget and timeline. Our stainless steel water bottles are designed to impress employees, clients, and stakeholders alike, with durability that lasts and customization that speaks to your brand. Led by Business Manager Pauline Chan, our team brings youthful energy and seasoned expertise to every order.

Elevate your brand’s presence with our premium stainless steel insulated water bottles, meticulously engineered for excellence in daily hydration, outdoor adventures, corporate gifting, and beyond. This comprehensive guide delves into the superior attributes of our products, tailored to satisfy both niche project specifications and large-scale commercial demands across diverse sectors.

We are committed to enriching your purchasing journey by providing valuable insights that empower informed and effective decisions. Partner with us to access hydration solutions that embody quality and innovation, supported by extensive manufacturing expertise.

Experience a seamless procurement process with our custom-made bottles, renowned for their durability, exceptional performance, and aesthetic appeal.

● 1892 – The Birth of Vacuum Insulation Technology

● 1904 – The First Commercial Thermos Bottle

● 1940s – Military and Industrial Adoption

● 1960s – Introduction of Stainless Steel Vacuum Flasks

● 1980s – Growth in Outdoor and Sports Markets

● 1990s – Shift Toward Health and Sustainability

● 2000s – The Rise of Customization and Branding

● 2010s – Innovation in Lid Technology and Design

● 2020s – Smart Features and Sustainability Focus

● Today – A Global Standard for Hydration

Designing an effective stainless steel insulated bottle involves several key considerations:

Shape and Size: Ergonomic designs that fit comfortably in hand and standard cup holders.

Mouth Opening: Wide-mouth designs facilitate easy cleaning and accommodate ice cubes, while narrow-mouth designs offer controlled sipping.

Base Diameter: Should be stable and compatible with car cup holders.

Height and Capacity: Common capacities range from 12 oz to 40 oz, catering to different hydration needs.

Several factors influence the pricing of stainless steel insulated bottles:

Material Quality: Premium materials like 18/8 stainless steel increase cost but offer better durability.

Insulation Technology: Advanced vacuum insulation techniques can raise prices.

Brand Name: Renowned brands may charge a premium for their reputation.

Additional Features: Accessories like interchangeable lids, built-in straws, or custom finishes add to the cost.

Production Volume: Bulk purchases often reduce the unit price.

We use 18/8 food-grade stainless steel, known for its corrosion resistance and durability. Each batch undergoes rigorous testing to ensure it meets international safety standards.

Advanced machinery cuts stainless steel sheets into precise dimensions. The pieces are then shaped into inner and outer bottle shells through processes like deep drawing and hydroforming, ensuring uniform thickness and structural integrity.

The inner and outer shells are welded together at the neck. Precision in this step is crucial to maintain the vacuum seal's integrity.

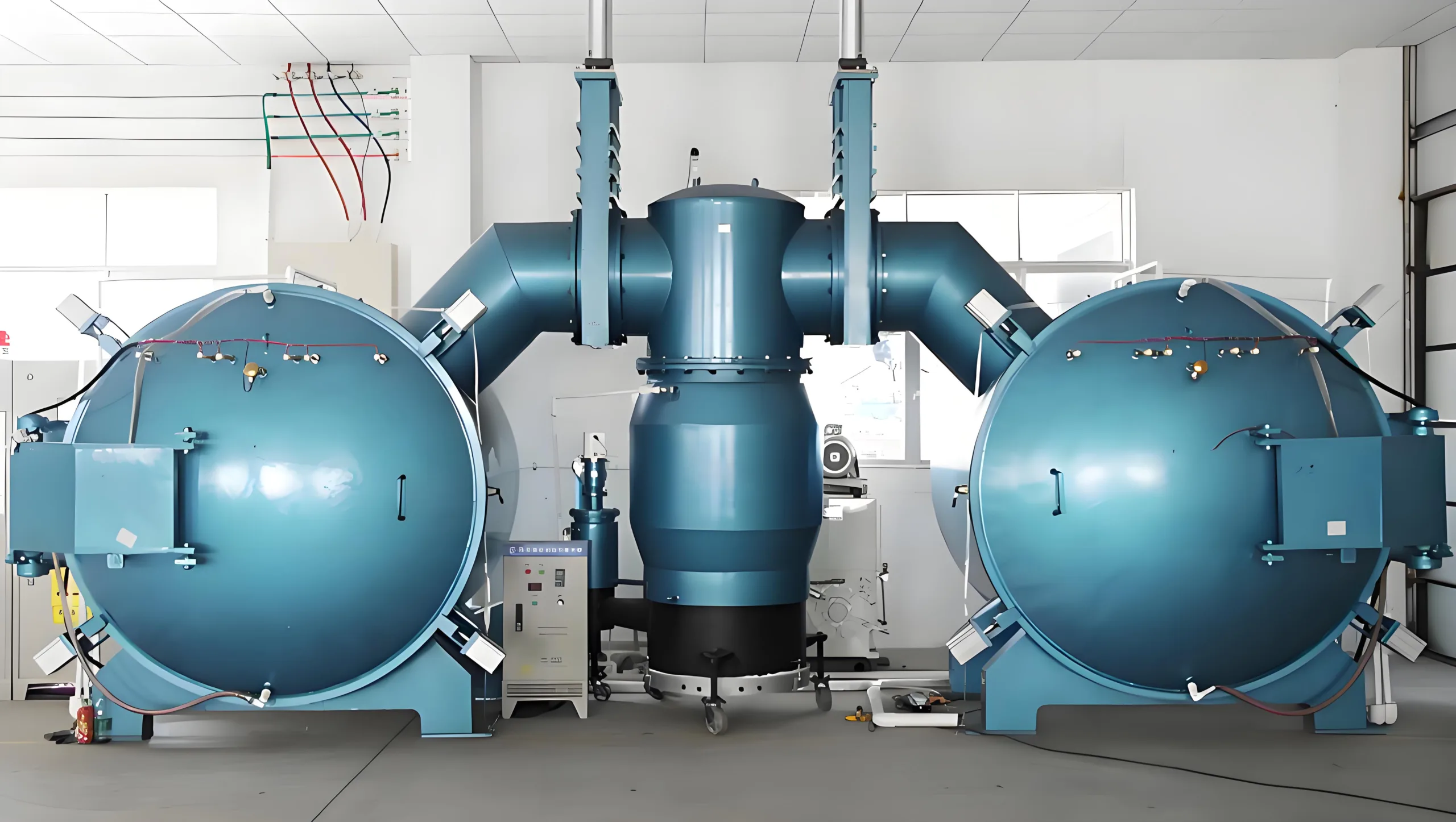

The space between the double walls is evacuated to create a vacuum, employing high-tech vacuum sealing equipment. This vacuum acts as an insulator, significantly reducing heat transfer.

Bottles undergo surface treatments such as polishing, powder coating, or painting to enhance aesthetics and grip. These finishes also provide additional protection against external element.

Each bottle undergoes rigorous testing, including:

Leak Testing: Ensures seals and lids function correctly.

Thermal Performance Testing: Verifies insulation effectiveness by measuring temperature retention over specified periods.

Durability Testing: Assesses resistance to impacts and drops.

Bottles are packaged using eco-friendly materials, with options for custom branding. Packaging is designed to protect the product during transit and appeal to consumers

Corrosion Resistance: Both 304 and 316 stainless steels exhibit high resistance to rust and corrosion, even when exposed to acidic or alkaline environments, ensuring longevity.

Durability: Stainless steel’s robust nature withstands impacts and drops, maintaining structural integrity over time.

Health Safety: Being non-reactive, stainless steel doesn’t leach chemicals into beverages, preserving taste and ensuring consumer safety.

Aesthetic Versatility: It offers a sleek, modern appearance and can be finished in various textures and colors, catering to diverse consumer preferences.

Designed with ergonomic features and often equipped with spout lids or straws for easy access during physical activities.

Typically fit into car cup holders and come with leak-proof lids, ideal for commuters.

Allow easy filling, cleaning, and the addition of ice cubes, suitable for those who prefer cold beverages.

Offer controlled pouring and drinking, reducing spills, and are often more compact.

Smaller in size with designs appealing to children, often featuring easy-to-use lids.

When evaluating different bottle types, consider the following factors:

Insulation Performance: Assess how long the bottle maintains beverage temperature under various conditions.

Capacity: Choose a size that aligns with the intended use, whether for short outings or extended trips.

Lid Design: Determine the convenience and functionality of the lid, such as ease of opening, drinking, and cleaning.

Portability: Consider the bottle’s weight, size, and features like handles or loops for carrying.

Ease of Cleaning: Bottles with fewer parts and wider openings are generally easier to clean, promoting better hygiene.

Durability: Stainless steel’s robust nature withstands impacts and drops, maintaining structural integrity over time.

Health Safety: Being non-reactive, stainless steel doesn’t leach chemicals into beverages, preserving taste and ensuring consumer safety.

Aesthetic Versatility: It offers a sleek, modern appearance and can be finished in various textures and colors, catering to diverse consumer preferences.

Investing in durable stainless steel bottles can significantly boost brand reputation:

Customer Satisfaction: High-quality, long-lasting products lead to positive reviews and repeat business.

Brand Exposure: Durable bottles used over extended periods serve as continuous advertisements, increasing brand visibility.

Environmental Responsibility: Offering reusable, durable products aligns with sustainable practices, appealing to eco-conscious consumers.

Cost Efficiency: Reduced returns and warranty claims due to product failures save costs and enhance profitability.

To ensure the longevity and safety of stainless steel bottles:

Avoid Dishwasher Use: Hand wash to maintain the integrity of insulation and exterior finishes.

Do Not Microwave: Metal components are not microwave-safe and can cause hazards.

Limit Freezer Use: Freezing can damage the vacuum seal and compromise insulation.

Handle with Care: While durable, repeated heavy impacts can dent the bottle and affect performance.

Proper maintenance ensures optimal performance and hygiene:

Regular Cleaning: Rinse after each use and wash with warm, soapy water to prevent residue buildup.

Deep Cleaning: Periodically use a mixture of vinegar or baking soda with water to remove stubborn stains and odors.

Drying: Allow bottles to air dry completely before storing to prevent mold growth.

Seal Maintenance: Inspect and clean rubber seals or gaskets regularly to ensure leak-proof performance.

Stainless steel insulated bottles are versatile and cater to various applications:

Ideal for hikers, cyclists, and athletes needing temperature-controlled hydration during activities.

Customized bottles serve as effective marketing tools, showcasing brand commitment to quality and sustainability.

Encourages regular water intake, promoting health and productivity in educational and professional settings.

Provides a convenient solution for maintaining beverage temperature during transit, enhancing the travel experience.

Selecting a reliable supplier is crucial for product quality and business success:

Certifications: Ensure the supplier complies with international standards such as ISO, FDA, or LFGB, indicating adherence to quality and safety protocols.

Manufacturing Capabilities: Assess the supplier’s production capacity, technological expertise, and ability to meet customization requirements.

Quality Assurance: Verify the existence of stringent quality control processes, including material inspections and product testing.

Reputation: Research customer reviews, industry standing, and case studies to gauge reliability and performance.

Communication: Effective and transparent communication ensures alignment on expectations, timelines, and specifications.

Durability: Stainless steel’s robust nature withstands impacts and drops, maintaining structural integrity over time.

Health Safety: Being non-reactive, stainless steel doesn’t leach chemicals into beverages, preserving taste and ensuring consumer safety.

Aesthetic Versatility: It offers a sleek, modern appearance and can be finished in various textures and colors, catering to diverse consumer preferences.

Need drinkware that fits your business? Contact CupCraft Supply today. You’ll get quick answers, custom solutions, and reliable support from our team—led by Pauline Chan—to meet your procurement needs fast and hassle-free.

© 2024 CupCraft Supply All Rights Reserved

Need drinkware that fits your business? Contact CupCraft Supply today. You’ll get quick answers, custom solutions, and reliable support from our team—led by Pauline Chan—to meet your procurement needs fast and hassle-free.