I’ve struggled before to find high-quality plastic water bottles. Defective bottles caused customer complaints, damaged my brand’s image, and cost me time and money.

The best premium plastic water bottles come from suppliers who strictly follow quality controls, comply with food-grade standards1, and adhere to key regulations. Clear checks and proven certifications make choosing suppliers easy.

Let me share what I learned after years of sourcing. This guide will help you avoid the pitfalls I encountered early on.

What are the most common quality control issues with plastic water bottles?

I've had bad experiences with quality. It’s painful receiving thousands of bottles only to find issues like leaks or weak materials.

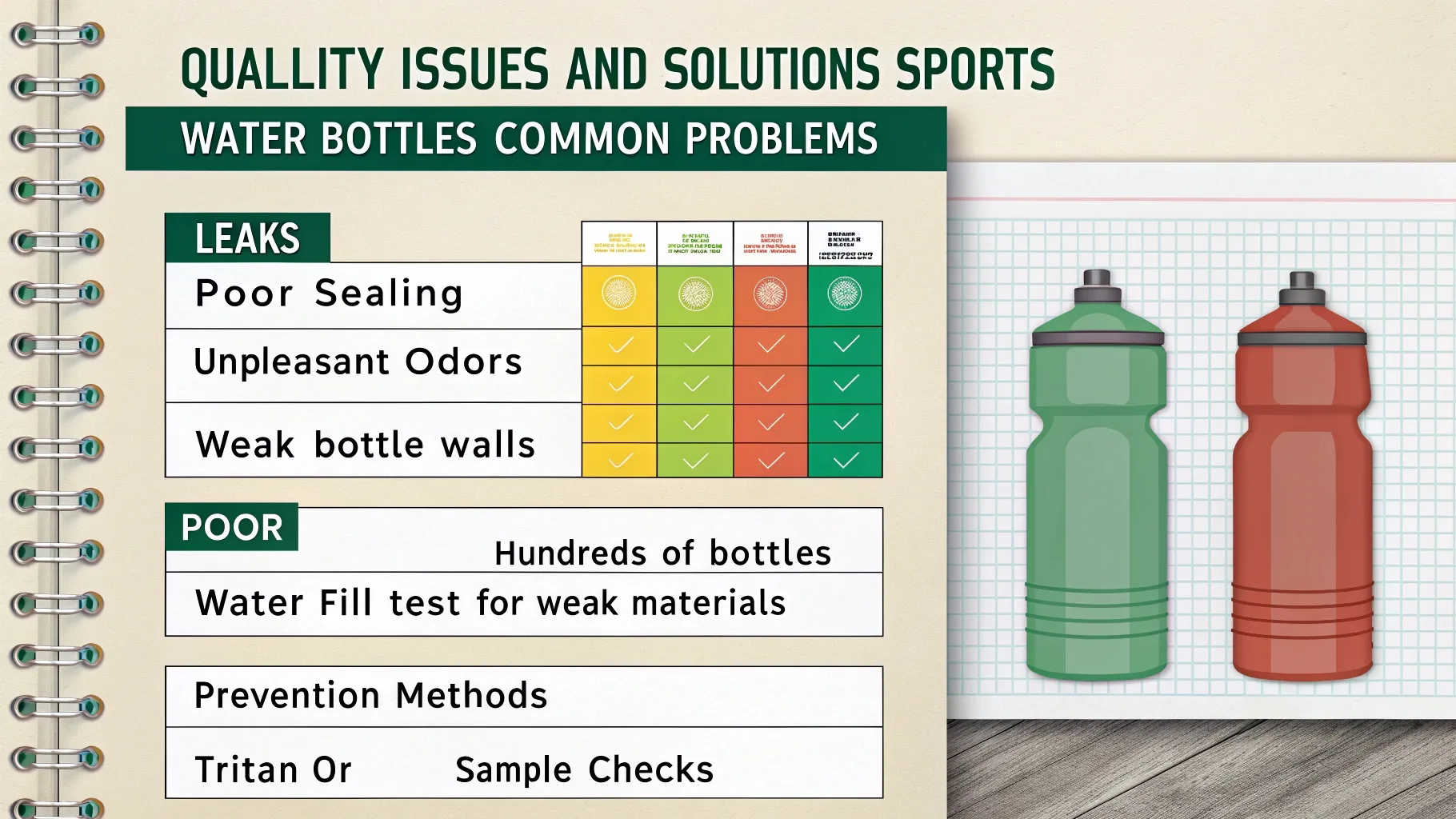

Common quality problems2 include leaks, poor sealing, unpleasant odors, weak bottle walls, and poor logo printing. Early checks and clear requirements reduce these risks significantly.

Issues and Solutions

| Issue | How I Identify It | Prevention |

|---|---|---|

| Leakage | Water fill test (24-hour test) | Tight sealing standards |

| Weak material | Drop test | Stronger plastic choices (Tritan or PETG) |

| Smell or taste | Initial sample checks | Use certified food-grade plastics |

| Poor printing | Visual inspection of samples | Ask for print test proofs |

My Past Mistakes

Once I skipped testing logos carefully. Hundreds of bottles had blurry logos. Now, I never skip detailed sample checks.

How can I ensure the quality of the plastic water bottles I purchase?

Early on, I worried about receiving poor-quality bottles after ordering. I needed an easy way to ensure quality before delivery.

To ensure quality, I request detailed samples, perform basic physical tests (drop, leak-proof), review quality certifications3, and always visit factories when possible. These steps confirm product quality upfront.

Quality Control Steps I Use

My Quality Control Checklist:

- Sample inspection: Always order at least two samples.

- Durability testing: Drop, squeeze, and leak-proof tests.

- Visual inspection: Logo clarity, bottle transparency, color consistency.

- Request quality reports: Ask for previous client quality reports or inspection documents.

How I Ensure Consistent Quality

I schedule regular factory visits whenever possible. Meeting suppliers in person and reviewing their production processes gives me confidence. Suppliers who welcome my checks are usually trustworthy.

How do I check if a plastic water bottle meets food-grade standards?

Food safety is always my top concern. Clients demand clear proof that our bottles are safe for daily use.

To verify food-grade standards1, I request FDA, LFGB, or EU food-contact certificates from suppliers. I also perform basic smell and taste tests to confirm there are no strange odors or tastes.

Steps for Confirming Food-Grade Status

| Action | Purpose |

|---|---|

| Ask for Certification | Confirm regulatory compliance4 |

| Check Material Labels | Verify BPA-free or food-safe materials (PP, Tritan, PETG) |

| Simple Tests | Check for odors, taste neutrality, and clarity |

My Quick Test Tip

Fill the sample with water and leave it overnight. Next morning, check for unusual taste or odors. This simple test has never failed me.

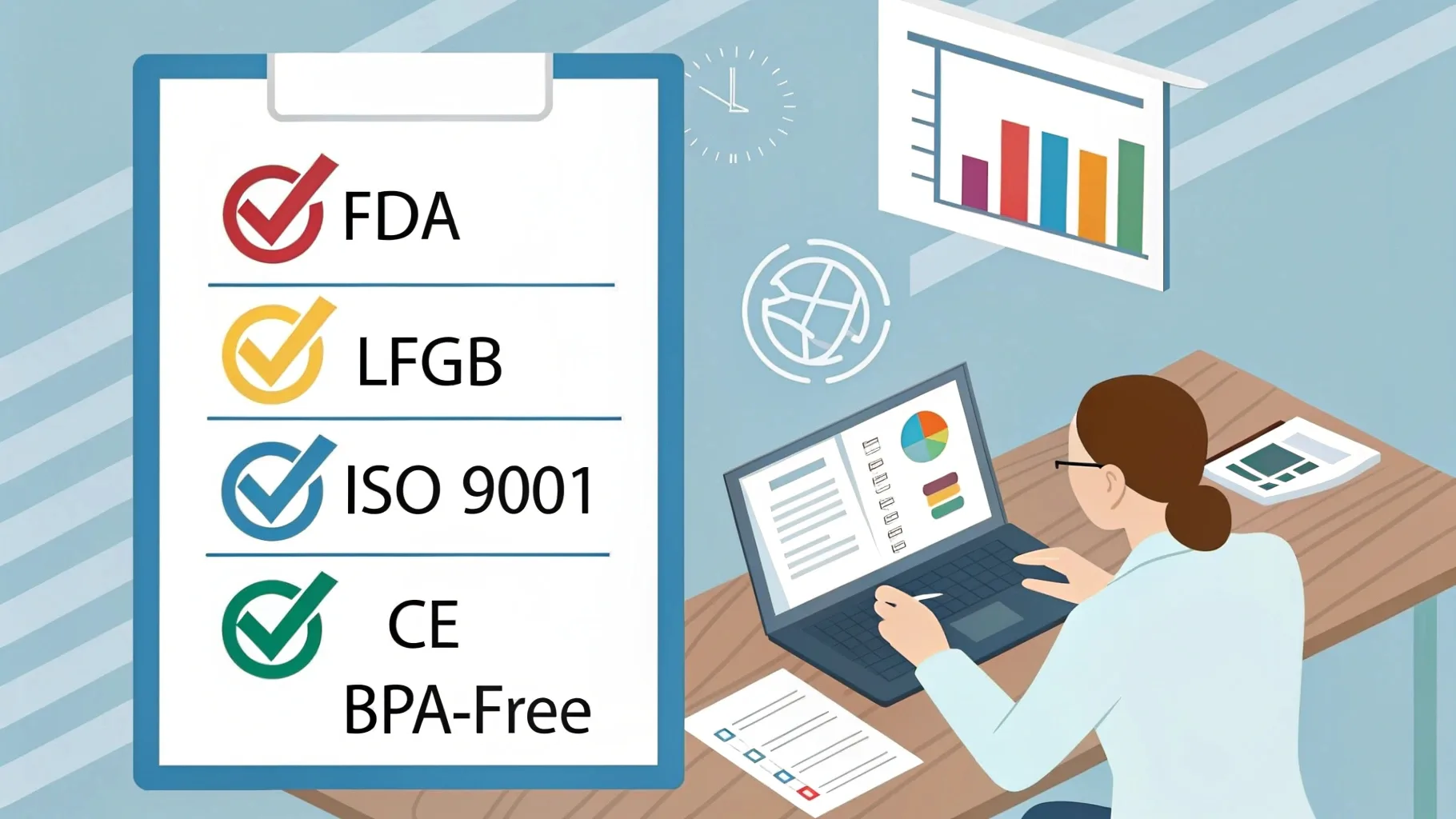

What certifications should I look for in plastic water bottle suppliers?

Early on, I didn't know which certifications mattered. Now I rely heavily on clear certifications to choose suppliers quickly.

Suppliers with FDA, LFGB, ISO 9001, CE, and BPA-free certifications3 assure me of reliable quality, safety compliance, and manufacturing consistency. These certificates indicate reliable standards and build trust.

Crucial Certifications Explained

| Certification | Meaning | Importance |

|---|---|---|

| FDA | Approved for food use in USA | Essential for North American markets |

| LFGB | Meets EU food safety regulations | Crucial for Europe sales |

| ISO 9001 | Consistent quality management | Indicates reliable processes |

| CE | European health & safety compliance | Vital for European distribution |

My Method for Checking Certifications

I always ask suppliers to provide clear PDF copies or certification links. I verify them online through official certification bodies or reputable third-party platforms.

What key regulations do premium plastic water bottle manufacturers follow?

Regulations can feel overwhelming. In the past, I overlooked important ones and faced setbacks later.

Top manufacturers follow regulations4 like FDA (USA), LFGB (EU), Proposition 65 (California), and REACH (EU chemicals). Adhering to these ensures compliance, safety, and protects brand reputation.

Important Regulations to Know

| Regulation | Applies to | Importance |

|---|---|---|

| FDA | US Market | Ensures bottles meet US safety standards |

| LFGB | EU Market | Compliance with strict EU food safety laws |

| Proposition 65 | California Market | Protects against hazardous chemicals |

| REACH | EU Chemical Standards | Controls chemicals and protects human health |

My Advice on Regulations

Stay proactive by regularly reviewing regulatory updates. Suppliers who stay updated help you avoid compliance issues and potential legal troubles.

Conclusion

Choosing premium plastic water bottles isn’t difficult if you know what to check. Clear quality controls, verifiable food-grade standards, and adherence to global regulations guide my decision-making process and protect my brand.

-

This guide explains how to verify whether a plastic water bottle is food-grade, covering essential materials and tests.

-

Understanding common quality control issues helps businesses avoid defective products and ensures high standards.

-

Knowing which certifications matter helps businesses choose reliable suppliers with proven quality assurance.

-

Staying compliant with key regulations ensures legal protection and product safety for international markets.